Cellulose film packaging is a bio-compostable packaging solution manufactured from wood or cotton, both of which are easily compostable. Besides cellulose film packaging extends the shelf life of fresh produce products by controlling the moisture content.

How is cellulose used in packaging?

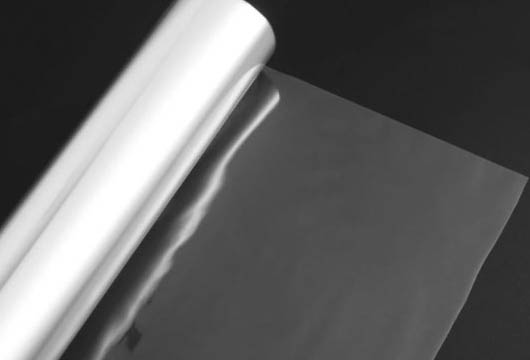

Cellophane is a thin, transparent, and completely biodegradable film or sheet manufactured from regenerated cellulose. Cellophane is useful for food packaging due to its low permeability to air, oils, greases, bacteria, and water. It has, therefore, been used as a food packaging material for nearly a century.

How is cellulose acetate film made?

Cellulose acetate is typically made from wood pulp through reactions with acetic acid and acetic anhydride in the presence of sulfuric acid to form cellulose triacetate. The triacetate is then partially hydrolyzed to the desired degree of substitution.

A transparent film manufactured from pulp. Cellulose films are made from cellulose. (Cellulose: A main substance of plant cell walls) The calorific value generated with combustion is low and no secondary pollution occurs by combustion gas.

How do you make cellulose plastic?

Cellulose plastics are manufactured using softwood trees as the basic raw material. Barks of the tree are separated and can be used as an energy source in the production. To segregate cellulose fiber from the tree, the tree is cooked or heated in a digester.

If you are in biodegradable film business,you may like

Recommend Reading

Post time: Sep-15-2022