Cellulose Films

Cellulose film packaging is a bio-compostable packaging solution manufactured from wood or cotton, both of which are easily compostable. Besides cellulose film packaging extends the shelf life of fresh produce products by controlling the moisture content.

Cellulose-based materials, like paper and board, are commonly used in packaging. They are light-weight, durable, bio-based and easily recyclable which have made them a popular packaging material.

Features:

Material Description

Typical physical performance parameters

| Item | Test method | Unit | Test Results |

| Material | - | - | CAF |

| Thickness | - | micron | 25 |

| Quantitative | - | m²/kg | 28.6 |

| - | g/m² | 35 | |

| Water vapor oxygen transmission rate | ASTM E 96 | g/m².24 Hrs | 35 |

| ASTM F1927 | cc/m².24 Hrs | 5 | |

| Transmittance | ASTM D 2457 | units | 102 |

| Friction (coating mask to film) | ASTM D 1894 | Static dynamic | 0.30/0.25 |

| Transmittance | Static dynamic | units | 102 |

| Tensile strength | ASTM D 882 | N/15mm | Longitudinal-56.9/Horizontal-24.7 |

| Elongation at break | ASTM D 882 | % | Longitudinal-22.8/Horizontal-50.7 |

| Heat sealing temperature | - | ℃ | 120-130 |

| Heat sealing strength | 120℃、0.07Mpa and 1 Second | g(f)/37mm | 300 |

| Surface Tension | - | dyne | 36-40 |

| Effect | - | - | red, green, orange, blue, transparent |

| Width | - | MM | 1020 |

| Length | - | M | 4000 |

Advantage

Both average gauge and yield are controlled to better than ± 5% of the nominal values. The crossfilm thickness;profile or variation will not exceed ± 3% of the average gauge.

Main Application

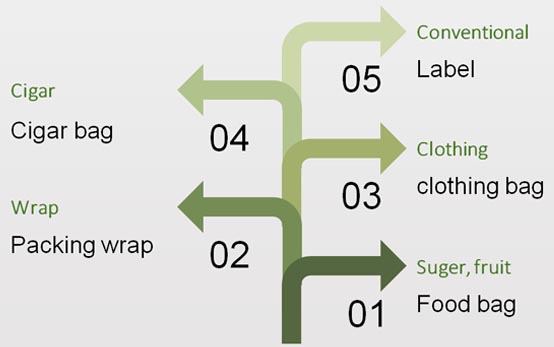

Other than for cellophane tapes, they are used for pharmaceutical products as medicine packaging. Widely used in food packaging, cigarette packaging, clothing bags, labels; For food product purposes, they are often used for candy and chocolate packaging.

Sustainable Coffee Packaging & Eco-Friendly Tea Packaging

In order to maintain the aromatics and rich flavors that are crucially important to your coffee and tea products, the right packaging can make the difference between a winning SKU and a stale blend. As a category that is extremely sensitive to UV rays, moisture and oxygen, and usually has a long lifespan (1-2 years), we know that finding the right packaging manufacturer can often be one of your company’s biggest challenges.

At YITO, we’re no strangers to the coffee and tea industry. After making the switch to compostable product packaging, our long list of customers in this space agrees that our eco-friendly cellulose films are the perfect solution for meeting their complex needs.

Whether you’re on a mission to eliminate wasteful single-use pods without compromising on convenience, or in a more traditional space looking to make sustainable choices, YITO has everything your brand needs to extend product shelf-life and succeed.

Our films provide:

· An excellent aroma barrier that prevents coffee and tea from airing out

· Superior oxygen and moisture protection

· Anti-static properties

· Opaque packaging options to eliminate UV damage

· Clarity and gloss for product over-wrap

Compostable Snack Bags And Dried Food Packaging

Individually-wrapped snacks and dried foods are perfect for vending machines, individual resale, or grab-and-go treats for your busy customers. Unfortunately, these products are often wrapped in petroleum-based plastic packaging that generates far too much waste for foods that are consumed so quickly. What’s preventing many manufacturers from switching to compostable packaging materials for food, however, is the belief that plant-based packaging won’t be able to cover all of the specs necessary in prolonging their shelf-life.

With YITO, it’s possible to have packaging that is better for the earth, but can withstand the test of time when it comes to protecting your brand’s packaged snacks and dried foods.

Our cellulose-based food packaging film delivers:

· A high oxygen barrier

· Excellent grease resistance

· Protection against mineral oil contamination

· Light and durable materials

· Exceptional seal integrity for heat seal flow-wrap

Compostable Stick Packs

Single serving stick packs are becoming a popular format for a variety of dry products. While their convenience is undeniable, the problem is that they’re quick to use and just as quick to toss into the garbage.

To avoid the mounds of plastic that stick packs leave behind, YITO offers an eco-friendly alternative that blends convenience and sustainability.

YITO cellulose films are perfect for single use stick packs due to their:

· High barrier that prevents oxygen and moisture from damaging your goods

· Excellent easy-tear properties for opening on-the-go

· Their shape and size customizability

Eco-Friendly Chocolate Packaging & Confectionery Packaging

Half the appeal of chocolate and confectionery products is decidedly in their packaging. As your customers browse the snack aisle, eye-popping treats will often be the ones that appeal the most. That’s why wrapping your brand’s sweets in an enticing package is extremely important in this category. Looks aside, your customers also care about the environmental impact your wrappers are making. In the same way that they carefully study the ingredient list and nutritional facts, your customers will be interested in knowing that your packaging is ethically-sourced, biodegradable, and compostable. YITO cellulose films can give your brand the extra edge, and you the peace of mind that your packaging gives back.

YITO cellulose films are suitable for easy to open bags, pouches, individually wrapped chocolates or to protectively overwrap chocolate bars.

They are specifically suited for the chocolate and confectionery industry thanks to their:

· High barrier to water vapor, gases and aroma

· Wide range of colors for on-shelf differentiation

· Range of moisture barriers to suit product requirements

· Strong seals

· Print-friendly nature

· Superior gloss and clarity

· Dead-fold for twist applications

Compostable Packaging For Produce

With its short lifespan, fresh produce is a category that needs to move towards sustainable packaging practices. Your produce is biodegradable and compostable, so why shouldn’t the packaging do the same?

That being said, we understand that there is a unique set of challenges when it comes to packaging produce. To protect your delicate products and extend their shelf-life, for example, we know that all packaging materials need to be breathable and moisture-resistant. In order for your customers to know that they’re getting the best possible produce, your retail packaging also needs to be crystal clear, with easy visibility of your product. YITO understands your specific needs and will happily accommodate them with our custom solutions for fresh food packaging.

YITO cellulose films are perfect for your products because of their:

· Excellent clarity

· Tailored moisture barrier, to extend shelf life

· Breathability, to prevent fogging in chill cabinet conditions

Eco-Friendly Bakery Packaging

Freshly baked bread deserves a sealed package that can keep it tasting like it just came out of the oven. Improperly packaged baked goods can quickly become dry and stale, especially when exposed to oxygen and moisture. YITO packaging films are designed to protect and preserve whatever’s inside, including high-demand products such as bread and pastries.

Our certified compostable cellulose films are great for baked goods because they are:

· Semi-permeable to moisture

· Heat-sealable on both sides

· An excellent barrier to oxygen

· Formulated for print

Custom Food Service Packaging

Maintaining a clean and healthy environment that meets foodservice health codes should always be number one on your list. In order to remain fully compliant, everything from the food to the forks often comes individually wrapped in its own sealed package. Unfortunately, this means that foodservice providers often leave behind a large amount of plastic packaging that will never biodegrade or compost.

With YITO compostable product packaging this issue can be avoided, while maintaining the integrity of the products sealed within. This major step towards a commitment to sustainability will help reduce plastic waste in an impactful way and won’t take much effort on your company’s part.

At YITO, we know the necessary packaging requirements you need to succeed in the industry. Our products are:

· Crystal clear for product presentation

· Compatible with fiber board for laminations

· Breathable

· Heat-sealable

· Stiff and durable

Compostable Bags And Sustainable Office Supplies

Smaller items such as envelopes and notebooks often need to be packaged for presentation and protection.

By choosing YITO cellulose packaging material rather than plastic films, your company will demonstrate its eco-friendly practices. As packaging that gets removed immediately after purchase, it’s all-the-more important that it’s readily compostable and biodegradable, ensuring that it doesn’t take a lifetime to decompose.

YITO is the answer to your bag-making needs. Our cellulose films have excellent:

· Heat seal capabilities

· High gloss for a refined look

· Clarity for product visibility

· Lightweight, protective, and durable cellulose packaging material

What are the benefits of cellulose products?

It is created from cellulose harvested from plants, it is a sustainable product sourced from bio-based, renewable resources.

Cellulose film packaging is biodegradable. Tests have shown that cellulose packaging biodegrades in 28–60 days if the product is uncoated and 80–120 days if coated. It also degrades in the water in 10 days if it’s uncoated and around a month if it’s coated.

Biodegradable cellophane bags resist moisture and water vapor, making them an excellent choice for displaying and storing food items.

It is heat sealable. With the right tools, you can quickly and easily heat seal and protect food products stored in cellophane bags.

When handling cellulose films at the time of preserving, transporting and processing—temperature, humidity and pressure, etc. affect the cellulose film's quality. It is recommended to use them following each of the terms below.

①Temperature and humidity

Temperature around 20 degrees Celsius and humidity around 55% are the most appropriate storage environment conditions for cellulose films. For use in winter, it is preferable to use them after keeping them wrapped in a temperature and humidity-controlled room for over 24 hours.

②Store in a place where direct sunlight can be avoided.

③Avoid placing materials directly on the floor. Stack them on shelves.

④Do not apply extreme loads on the materials during storage.

Avoid stacking in tiers as much as possible. Avoid stacking laterally to prevent shape deformation.

⑤Do not unwrap until immediately before use. (Re-wrap in high moisture-proof films, such as aluminum-metallized film to store unused remaining parts.)

⑥Ideally, the storing period should be 60 days or less.

⑦Handle with care to prevent scratches from impacts and flaws on the edges.

FAQ

It is seen most often in the food and beverage industry, pharmaceuticals, personal care, home care, and retail sectors. Using cellulose to create biodegradable products that can replace petroleum-based plastics will reduce the impact these packaging materials have on the environment. Bioplastics are biodegradable or compostable plastics made from natural substances instead of petrolem. The idea is that these new, earthier plastics can replace the harmful ones in our food and around our home.

If you currently use plastic bags for candies, nuts, baked goods, etc., cellulose packaging bags are a perfect alternative. Made from cellulose derived from wood pulp, our bags are strong, crystal clear and certified compostable. We have been got FSC certificate and the compostable certificate.

We offer two styles of biodegradable cellophane bags in a variety of sizes: Flat cellulose bags, Gusseted cellulose bags

The cellulose bag can print FSC logo on it.

Cellulose film is created from the cellulose taken from cotton, wood, hemp, or other sustainably harvested natural sources. It starts as a white dissolving pulp, which is 92%–98% cellulose.

1. Keep the original packaging away from heat and direct sunlight.

2. Storage conditions: temperature: 17-23°C, relative humidity: 35-55%;

3. The product should be used up within 6 months from the delivery date.

4. Follow the first-in first-out principle. It should be transferred to the processing workshop 24 hours before use.

1. The two sides of the package are reinforced with cardboard or foam, and the whole periphery is wrapped with air cushion and wrapped with stretch film;

2. All around and at the top of the wooden support are sealed with stretch film, and the product certificate is pasted on the outside, indicating the product name, specification, batch number, length, number of joints, production date, factory name, shelf life, etc.Inside and outside the package must be clearly marked the direction of unwinding.

YITO Packaging is the leading provider of compostable cellulose films. We offer a complete one-stop compostable film solution for sustainable business.