Comparison of Five Types of Smoke cigarette tobacco Films

1) PVC shrink film

High desity , Due to poor optical performance, insufficient heat sealing performance to meet the requirements of high-speed charter machines, and unfriendly environment, it was abandoned by the cigarette industry without comprehensive promotion;

2) cellophane film

Regenerated cellulose, also known as cellophane, is characterized by high transparency, good glossiness, high stiffness, good printability, and no need for any treatment before printing; It has anti-static properties and is not easy to absorb dust. But cellulite is more important( ρ≈ 1.31 g/cm3), with hydrophilicity and poor moisture resistance, the film is prone to deformation due to temperature and humidity, and cannot be directly heat sealed. It can only be manually packaged and cannot adapt to high-speed cigarette packaging machines. Moreover, the use of cellophane for cigarette packaging has a high unit price, which gradually replaced it;

3) Polyvinylidene chloride (PVDC)

The coated tobacco film has excellent low-temperature heat sealing performance (heat sealing temperature is 107 ℃~140 ℃), and the friction coefficient during the packaging process is less than 0.3, indicating good anti-static performance.

4) BOPP smoke film

It has unparalleled characteristics such as low haze, high gloss, wide heat sealing range, high heat sealing strength, excellent water vapor barrier ability, uniform thickness, wide shrinkage control range, high stiffness, and environmental friendliness, gradually becoming the main film packaging material for cigarettes.

5) BOPLA film and PLA film

BOPLA stands for Polylactic Acid. Made from renewable resources such as corn starch or sugar cane, it’s a natural polymer designed to substitute widely used petroleum-based plastics like PET (polyethene terephthalate). In the packaging industry, PLA are often used for plastic bags and food containers.

Adopting advanced packaging technology and methods

In order to extend the shelf life of food, new packaging technologies have been continuously developed, such as active packaging, anti mold packaging, moisture-proof packaging, anti fog packaging, anti-static packaging, selective breathable packaging, anti slip packaging, buffer packaging, etc. These new technologies have been widely applied in developed countries, but they are not widely used in China, and some methods are still blank. The application of these advanced technologies can significantly improve the protective function of packaging.

Select packaging machinery and equipment that are compatible with food processing technology

To meet the needs of food processing technology, various new packaging equipment have been developed, such as vacuum packaging machines, vacuum inflatable packaging machines, heat shrink packaging machines, blister packaging machines, body mounted packaging machines, sheet thermal forming equipment, liquid filling machines, forming/filling/sealing packaging machines, sterile packaging complete sets of equipment, etc. Choosing or designing packaging machinery that is compatible with food processing technology and production capacity based on the selected packaging materials and packaging process methods is the guarantee of successful packaging.

Brand awareness in packaging decoration design and packaging design

The packaging and decoration design should conform to the preferences and habits of consumers and consumers in the exporting country. It is best to coordinate the pattern design with the interior. The trademark should be prominently placed and the text should comply with food requirements. The product description should be truthful. The trademark should be catchy, easy to understand, easy to circulate, and can play a widespread promotional role. The packaging design of famous brand products should have a brand awareness. Some product packaging is easy to change, which affects sales. For example, China’s Laoliutiao vinegar has a good reputation in Japan and Southeast Asia, but the sales volume decreases significantly after changing packaging, because consumers have doubts about the new packaging. So, a product should be scientifically packaged and cannot be easily changed.

1、 Requirements to be met for food grade packaging bags

Food grade packaging must meet the protection needs of all aspects of food

Food packaging requirements can block water vapor, gases, fats, and organic solvents;

2. According to the special requirements of actual production, add functions such as rust prevention, corrosion prevention, and electromagnetic radiation prevention;

3. Ensure food safety and pollution-free while extending food shelf life.

The main and auxiliary materials used in food grade packaging must not contain substances that may cause harm to the human body, or the content should be within the allowable range of national standards.

Due to the unique nature of food grade plastic packaging, only by strictly following production standards can products be approved and put into the market.

All inner packaging bags that come into contact with food strictly adhere to the production process of food grade packaging bags, which not only ensure safety and hygiene, but also ensure the delicious original taste.

Instead of food grade packaging bags, the main difference in material composition lies in the use of additives. If opening agents are added to the materials, they cannot be used for food packaging.

2、 How to distinguish between food grade and non food grade packaging bags?

When receiving the packaging bag, observe first. The brand new material has no odor, a good feel, a uniform texture, and bright colors. Only those that meet the standards are food grade and environmentally friendly bags that are safe and hygienic.

3、 Classification of food packaging bags

According to its application scope, it can be divided into:

Ordinary food packaging bags, vacuum food packaging bags, inflatable food packaging bags, boiled food packaging bags, steamed food packaging bags, and functional food packaging bags.

There are also many types of materials: plastic bags, aluminum foil bags, and composite bags are common.

Vacuum bags are used to extract and seal all the air inside the packaging, maintaining a highly depressurized state inside the bag. The scarcity of air is equivalent to a low oxygen effect, making it impossible for microorganisms to survive, in order to achieve the goal of fresh food and no occurrence of disease and decay.

Food aluminum foil bags are made from aluminum and other high barrier materials through dry compounding based on the unique properties of aluminum. Aluminum foil bags have excellent moisture resistance, barrier, light resistance, permeability resistance, and beautiful appearance.

Food grade composite bags are moisture-proof, cold resistant, and low temperature heat sealed with tensile strength .

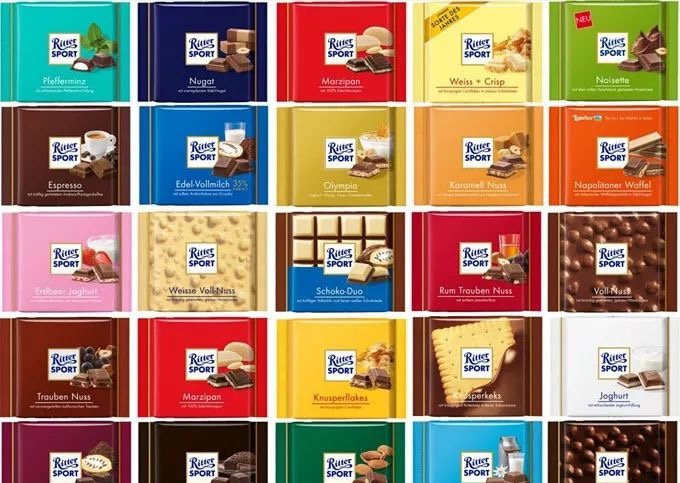

If you are looking for recyclable and compostable cigarette films and chocolate food packaging films , feel free to contact : williamchan@yitolibrary.com

Post time: Sep-22-2023