Across global supply chains, a fundamental shift is underway. Environmental regulations are tightening, traditional plastics are falling out of favor, and sustainable packaging is no longer a niche concern but a business imperative. Governments are implementing plastic bans and levies, while retailers and consumers are actively seeking brands aligned with green values. In this changing landscape, importers and distributors play a critical role—not only as middle links in the value chain but also as decision-makers who can influence sustainable transformation.

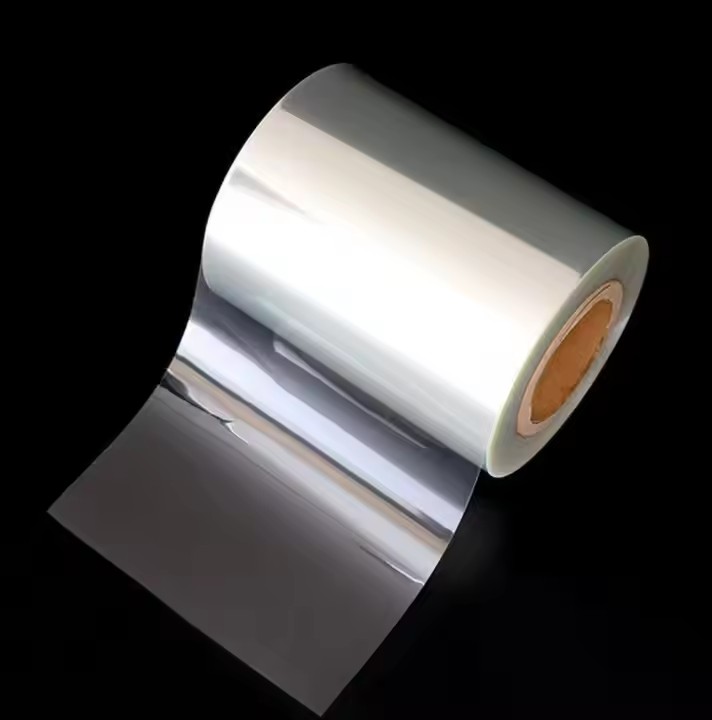

Biodegradable films, particularly those made from polylactic acid (PLA) and cellophane, are emerging as key solutions for reducing environmental impact without compromising on functionality. These materials represent a compelling opportunity to meet both regulatory requirements and market expectations. For businesses involved in packaging distribution, food export, or logistics, understanding the properties, applications, and strategic advantages of these films can be a crucial competitive differentiator.

This article explores the commercial potential of PLA and cellophane films, focusing on their relevance to B2B operations. It outlines their core attributes, compares their performance, and highlights how choosing the right biodegradable material can unlock value across multiple sectors.

What Are Biodegradable Films?

Biodegradable films are packaging materials designed to break down naturally through the action of microorganisms into harmless byproducts such as water, carbon dioxide, and biomass. Unlike conventional plastic films derived from petroleum, biodegradable films are typically made from renewable sources like corn starch or wood pulp. They are engineered to degrade under composting or environmental conditions, leaving no toxic residues or microplastics behind.

From a sustainability standpoint, biodegradable films offer an elegant solution to a pressing problem: how to maintain modern packaging performance while minimizing long-term environmental harm. For B2B buyers, the move toward biodegradable options is not only about ethics or compliance—it is also about aligning with the future of global trade.

Application Scenarios in B2B: Where It Pays Off

-

✅Fresh Produce Food Packaging

Biodegradable films are increasingly being used in the packaging of perishable goods. PLA cling films serve as compostable alternatives to traditional plastic wrap for fruits, vegetables, and meat products. These films provide excellent clarity and breathability, extending shelf life while minimizing moisture loss. PLA vacuum bags and fruit bags are also gaining popularity among food exporters and large-scale distributors seeking to meet international compostability standards.

For food processors, the use of PLA-based sausage casings and cellulose-derived multilayer pouches allows them to maintain food safety while enhancing the brand’s eco-friendly image. As consumer demand for clean-label and sustainable products grows, such packaging becomes a key differentiator on retail shelves.

-

✅Giftware, Stationery, and Retail Packaging

In the giftware and stationery sectors, cellophane packaging offers a compelling combination of sustainability and presentation. Its natural gloss and crisp texture elevate the look of greeting cards, bookmarks, art prints, and craft items, while still being compostable in a home environment. Retail distributors and wholesalers catering to boutique brands or eco-conscious consumers are embracing cellophane for its visual appeal and environmental credentials. PLA can also be used in decorative bags or envelopes for larger or custom-printed applications where sealing and durability are more important than rigidity. By switching from OPP or PVC to biodegradable alternatives, sellers gain not just a material upgrade, but a compelling story for their marketing and merchandising.

-

✅Logistics and Industrial Wrapping

Sustainability goals are also reshaping the industrial supply chain. In warehousing and distribution centers, PLA stretch film is being adopted as a viable substitute for petroleum-based pallet wraps. While slightly less elastic than PE stretch wrap, PLA film offers strong tensile performance and biodegradability—allowing businesses to reduce landfill waste and lower their plastic tax liabilities.

Fulfillment operations and logistics companies that provide services for brands with ESG mandates are particularly keen on biodegradable packaging. Incorporating these materials into shipping and bundling processes shows proactive environmental responsibility and creates long-term reputational value.

-

✅Foodservice and Disposable Packaging

Restaurants, caterers, and foodservice suppliers are under growing pressure to eliminate single-use plastics. PLA films offer a range of solutions such as compostable liners, sandwich wraps, and disposable tray covers that meet hygiene standards while aligning with zero-waste objectives. Cellulose-based casing films used for sausage and meat products provide a plant-derived alternative to plastic-based food wrapping. As more venues—from fast-casual eateries to premium hotels—transition toward circular waste systems, distributors offering biodegradable options are gaining a competitive advantage.

PLA vs. Cellophane: Which Suits Your Market?

-

✅Material Composition and Origin

PLA film is synthesized from fermented plant starches like corn, sugarcane, or cassava. It is classified as a bioplastic and offers a wide range of mechanical and barrier properties. Cellophane, by contrast, is produced by dissolving and regenerating cellulose from wood pulp or cotton linters, making it one of the oldest biodegradable films in commercial use.

Both materials are renewable, but cellophane is closer to paper in molecular structure, while PLA is closer to plastic, offering different behaviors in both processing and disposal.

-

✅Mechanical and Visual Properties

PLA films are known for their high transparency, tensile strength, and flexibility. They can be formed into stretch, shrink, or multilayer barrier films suitable for industrial packing and food protection. They also offer superior sealing properties and are compatible with a variety of forming equipment.

Cellophane film is more rigid and less heat-tolerant but excels in visual clarity, gloss, and tactile finish. Its crisp texture and shape retention make it perfect for applications where product display and aesthetic presentation are priorities.

Choosing between the two often depends on whether the application demands functionality under stress (favoring PLA) or visual enhancement and shelf appeal (favoring cellophane).

-

✅Degradation Profiles and Compostability

PLA films degrade in industrial composting facilities under specific temperature and moisture conditions, typically within 180 days. Home composting may not break down PLA efficiently without pre-treatment.

Cellophane, particularly uncoated versions, degrades rapidly in both industrial and home composting conditions—usually in 28 to 60 days. Even coated cellophane films typically break down within 120 days, depending on environmental conditions.

For markets lacking industrial composting infrastructure, cellophane may offer a better fit. In more developed regions with composting capabilities, PLA’s superior strength and multi-functionality can be fully leveraged.

-

✅Market Fit and Sector Priorities

PLA is especially well-suited for applications involving food safety, shelf life extension, and product integrity—making it ideal for fresh produce, logistics, and foodservice packaging. It is also increasingly adopted in retail pouches and branded flexible packaging.

Cellophane, with its elegant appearance and fast degradation cycle, works well for dry foods, cosmetics, cards, and promotional materials. It satisfies the needs of small and mid-sized enterprises seeking compostable materials without heavy industrial waste processing.

Ultimately, your target market, product type, and disposal infrastructure should guide the material selection.

Key Environmental Advantages

Carbon Footprint Reduction

Both PLA and cellophane offer lower life-cycle greenhouse gas emissions compared to traditional plastic films. Their use of renewable feedstocks and compostability helps close the loop in the packaging value chain. Companies adopting these materials can improve their Scope 3 emission profiles and report positive progress in sustainability reporting.

Non-Toxic and Microplastic-Free

Neither PLA nor cellophane releases harmful microplastics or toxins as they degrade. This contrasts sharply with the environmental legacy of conventional plastics, which fragment into particles that persist in soil and waterways. Biodegradable films present a cleaner alternative that aligns with marine safety and soil health objectives.

Certification and Compliance Benefits

Most biodegradable films are available with internationally recognized certifications such as EN13432, OK Compost, TÜV Austria, and BPI Compostable. These certifications not only demonstrate end-of-life viability but also make it easier for importers to meet local packaging regulations.

With tightening policies across Europe, North America, and Asia Pacific, certified biodegradable films help companies avoid penalties, enhance brand image, and enter eco-conscious retail channels more easily.

If your business is looking to align with global sustainability standards, now is the time to explore biodegradable film solutions. Whether you need PLA stretch wrap, compostable vacuum bags, cellophane card sleeves, or multilayer food pouches, YITO can offer tailored solutions at scale. Contact us today to discuss specifications, request certified samples, or explore private label options that meet your operational and environmental goals.

Related Products

Post time: Jun-09-2025