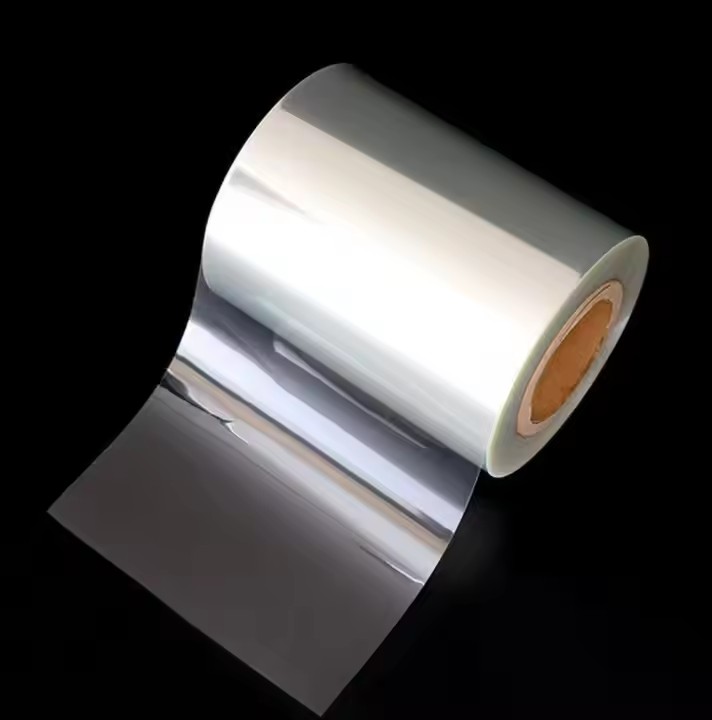

When businesses search for cellophane film manufacturers in India, they often expect to find reliable, cost-effective, and eco-friendly solutions. India’s packaging industry has indeed built a strong reputation for producing cellophane and cellulose-based films for food, gift wrapping, and industrial use. However, as global supply chains evolve, many companies are now exploring the advantages of importing from China—particularly with experienced suppliers like YITOPACK who combine quality, flexibility, and sustainability.

In this article, we’ll take a closer look at India’s cellophane film manufacturing landscape, explore potential challenges of sourcing directly from local producers, and explain why Chinese suppliers can often deliver better value—without compromising on quality.

Why India Has a Strong Cellophane Film Manufacturing Base

India’s packaging sector has grown rapidly over the past decade, driven by a booming retail market, rising consumer demand for sustainable products, and government initiatives to reduce plastic waste. Cellophane film, made from regenerated cellulose, fits perfectly into this shift toward eco-friendly packaging.

Key Production Regions

Several Indian states have developed specialized hubs for cellophane film manufacturing. Gujarat, Maharashtra, and Tamil Nadu are home to numerous factories producing transparent and semi-transparent films for diverse applications. A large producer in Gujarat, for example, has been supplying food-grade cellophane for over two decades, while a well-known company in Maharashtra specializes in colored and printed cellulose wraps.

Representative Manufacturers

1. G** Packaging Pvt. Ltd. (Gujarat)

-

Specialties: Transparent food-grade films, anti-fog coated wraps.

-

Export Markets: Middle East, Southeast Asia.

-

Capacity: Over 5,000 tons/year.

-

Note for Buyers: Strong in bulk orders but typically requires MOQs above 4–5 tons.

2. M** Films India Ltd. (Maharashtra)

-

Specialties: Colored, metallized, and custom-printed cellophane for premium gift wrapping.

-

Export Markets: Europe, Africa.

-

Capacity: Large-scale production with flexible printing options.

-

Note for Buyers: Lead times can stretch to 6–8 weeks in peak season.

3. S** Polypack Pvt. Ltd. (Tamil Nadu)

-

Specialties: Moisture-resistant cellulose films for bakery and snack packaging.

-

Export Markets: South Asia, Oceania.

-

Capacity: Mid-size facility with focus on coated films.

-

Note for Buyers: Offers niche coating services but may have limited roll widths.

Main Applications in the Indian Market

-

Food Packaging – Wrapping bakery products, confectionery, and fresh produce.

-

Gift Wrapping – Decorative transparent films for florists, retail stores, and event packaging.

-

Industrial Uses – Laminating layers in specialty papers, or moisture-resistant coatings.

Quality and Standards

Most established Indian manufacturers comply with ISO standards, and some meet FDA and EU food safety requirements. Their films typically range from 20 to 40 microns in thickness, with moisture barrier coatings and anti-fog properties available for specific applications.

Challenges of Sourcing Directly from Indian Manufacturers

High Minimum Order Quantities (MOQ)

Typical MOQs range from 3–5 tons, making trial runs difficult for smaller buyers.

Longer Lead Times

Production plus export logistics can result in 6–8 week delivery times, especially during festivals or export peaks.

Price Volatility

Raw material cost fluctuations and currency shifts can make long-term pricing agreements challenging.

Why Importing Cellophane Film from China Can Be a Smarter Option

China’s cellophane manufacturing sector is highly competitive, offering:

-

Flexible MOQ – As low as 300–500 kg for trial orders.

-

Material Variety – Traditional cellulose, PLA, colored, printed, and coated films.

-

Faster Lead Times – 2–4 weeks on average.

-

Integrated Export Support – Strong logistics networks and multiple major ports.

YITOPACK – Your Trusted Cellophane Film Supplier from China

About YITOPACK

-

Over 10 years of export experience.

-

Specialized in eco-friendly and biodegradable films.

-

YITO serves clients in food, retail, cosmetics, and industrial sectors.

Product Range

-

Transparent & semi-transparent cellophane

-

Food-grade wraps with compostable coatings

-

Colored & printed gift wrap films

-

PLA and other biodegradable options

Advantages

-

No MOQ for certain products

-

10–15 day production cycles

-

Global shipping and customs support

-

Sustainability compliance with compostable certifications

India’s cellophane film manufacturers—from G** Packaging in Gujarat** to M** Films in Maharashtra**—offer solid options for bulk buyers. But for businesses seeking lower MOQs, faster delivery, and greater customization, importing from China—especially with YITOPACK—can deliver better results.

By knowing the strengths and limits of each sourcing region, you can secure the right packaging partner for your business goals.

Related Products

Post time: Aug-11-2025